CEF polymers

Since 1961

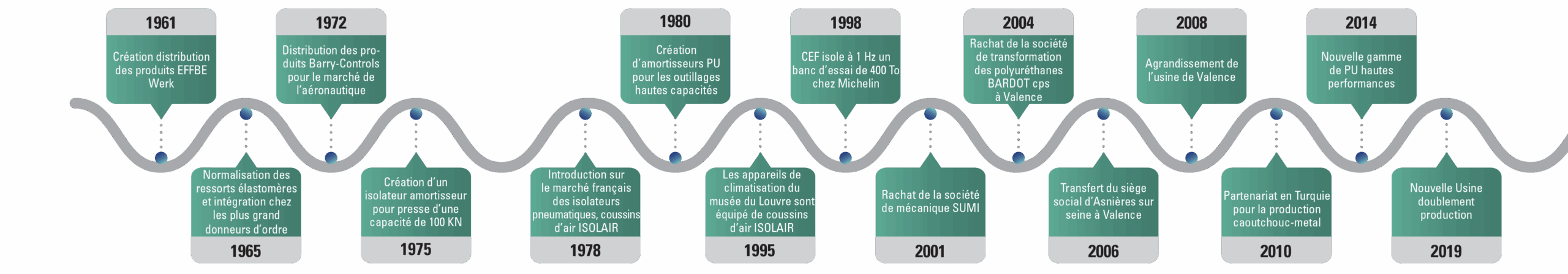

CEF POLYMERES

contributes to the reliability and optimization of mechanical assemblies. We design and produce elastomer solutions to deal with problems linked to vibration, shock, contact wear, chemical constraints and sealing. Our high-performance formulations, combined with our expertise in the field since 1961, ensure that you get the results you expect, and that we provide you with the best possible support in your development.

The quality we bring to our products will lower your costs. Elastomer parts represent a low value compared to other components, but are the ones that can cost you

the most if their longevity is limited or if they are poorly defined.

Industrial since

Antivibration rubber-metal molding solutions

Supports and shock absorbers, feet and wedges, plates and supports, air cushions - several ranges of solutions to combat vibration and shock.

Polyurethane Molding Solution

CEF Strathane polyurethane elastomers have very high physical and mechanical properties. We produce flexible or very rigid parts from 20 Sh A to 99 Sh A. The gravity casting process, identical to that used for foundry work, does not require major investment in molds. What's more, it enables rapid production start-up, even for single parts.

Tire Solutions

Comprimatic diaphragm cylinders are used for applications where sensitive, precise adjustment is required.