CEF polymères

Depuis 1961

La qualité que nous apportons à nos produits vous permettrons de faire baisser vos coûts. Les pièces élastomères représentent une faible valeur au regard des autres composants mais sont ceux qui peuvent vous coûter le plus cher si leur longévité est limitée ou si ils sont mal définies.

Depuis 1961

CEF POLYMERES

contribue à la fiabilisation et l’optimisation des ensembles mécaniques. Nous concevons et produisons des solutions élastomères qui permettent de traiter les problématiques liées aux vibrations, chocs, usure par contact, contraintes chimiques, étanchéité. Nos formulations hautes performances combinées à nos expertises métiers depuis 1961 sont l’assurance d’obtenir le résultat escompté et d’être accompagné au mieux dans vos développements.

Solution Moulage caoutchouc-métal Antivibratoires

Supports et amortisseurs, pieds et cales, plaques et appuis, coussins d’air plusieurs gammes de solutions pour lutter contre les vibrations et les chocs

Solution Moulage Polyuréthanes

Les élastomères de polyuréthane CEF Strathane sont dotés de propriétés physiques et mécaniques très élevées. Nous produisons des pièces souples ou très rigide de 20 Sh A à 99 Sh A. Le process pour coulée gravitaire, identique à la fonderie, ne demande pas des investissements en moule important. De plus, la permet une mise en production rapide y compris pour des pièces à l’unité.

Solutions Pneumatiques

Les vérins à membrane Comprimatic permettent de réaliser des actions où un réglage sensible et précis est exigé.

RETROUVEZ NOUS LORS DES SALONS

JOIN US AT TRADESHOWS

CEF POLYMÈRES

Nos marques

ACTUALITÉ

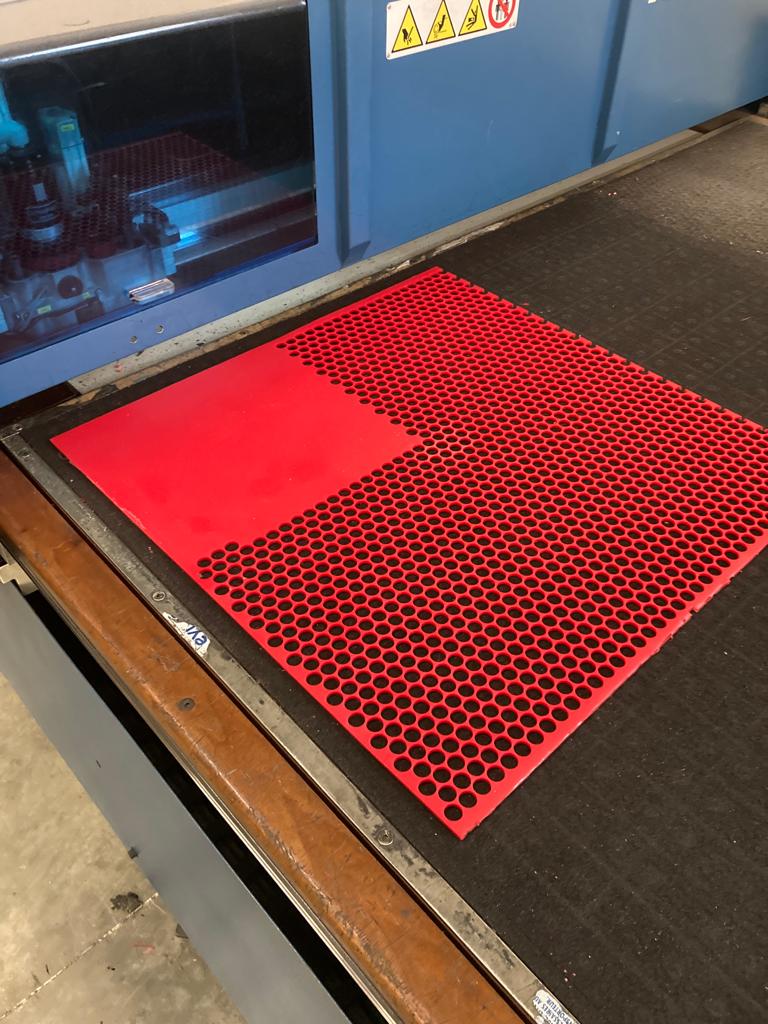

Nouvel investissement productif dans une machine ATOM pour la découpe cnc de produits plats

Automatisation des découpes de joints, racleurs, amortisseurs, rondelles…..

Nos valeurs

- Accompagner nos clients dans leur développement.

- Rechercher la qualité optimale au regard des objectifs de coût.

- Pérénité de solutions proposées. Nous sommes à même de remplacer les produits que nous avons vendu dans les années 60.

- Encourager la promotion et la créativité de nos collaborateurs.

- Préserver un partenariat gagnant avec nos sous-traitants.

- Maintenir une organisation réactive.

- Utiliser les produits chimique les moins nocifs et polluants.

EXPERTISE

Un savoir-faire reconnue dans la conception et production de composants élastomères pour contraintes dynamiques. CEF Polymères est l’une des rares sociétés à pouvoir maitriser la transformation de gammes d’élastomères qui sont complémentaires mais très différents dans leur process.

- Le polyuréthane de 20 Sh A à 80 Sh D.

- Le caoutchouc – métal NR NBR CR EPDM VMQ de 35 Sh A à 90 Sh A

- 2 sites de production dédié suivant métier moulage polyuréthane et caoutchouc-métal

- Production France et Low Cost.

- Partenariat et Sourcing européen.

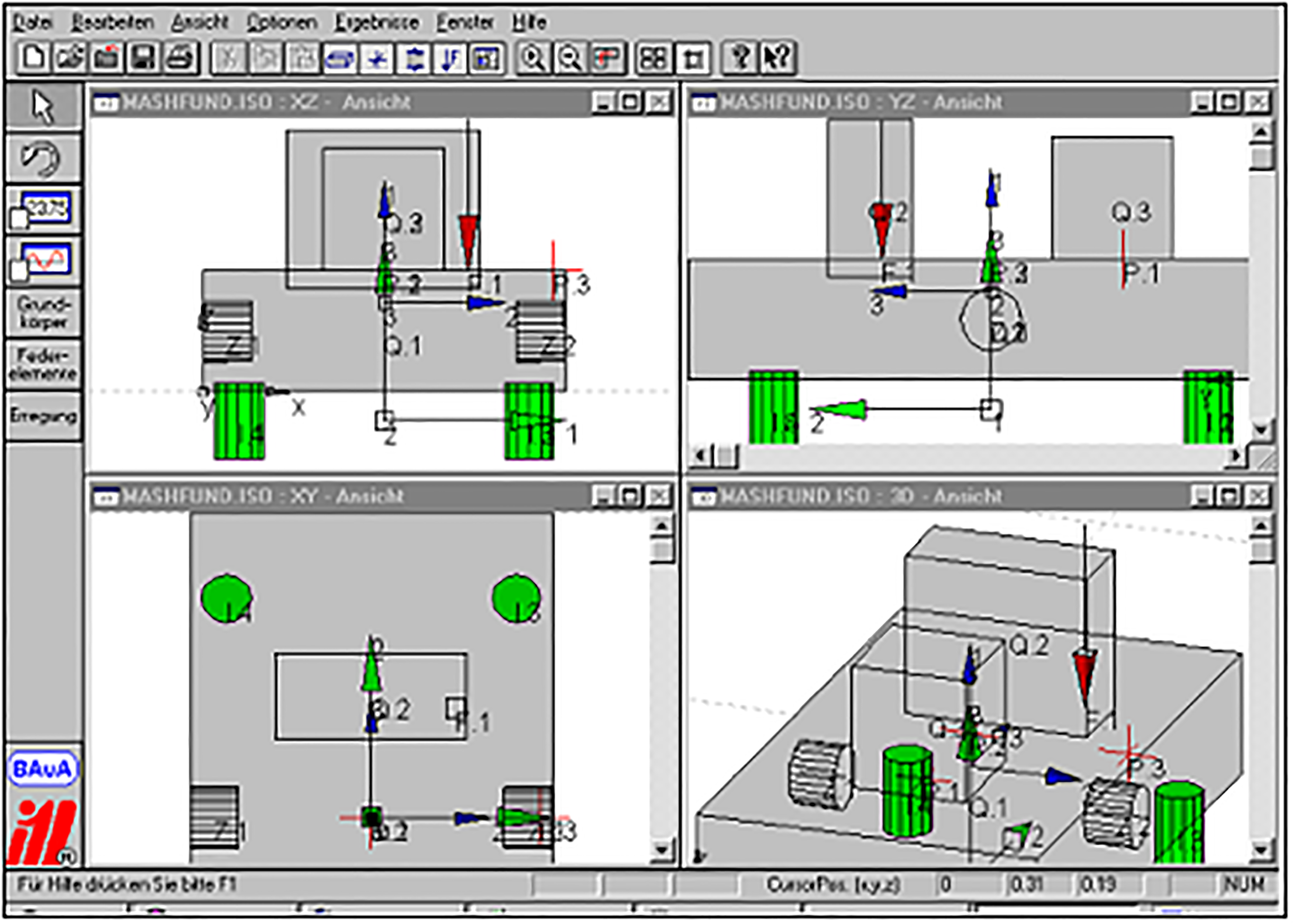

- Bureau d’études intégré disposant d’outils de calculs spécifiques métiers.

Polyuréthanes de coulée en basse pression gravitaire

8 machines de coulées, 6 étuves, 3 Tables chauffantes

Caoutchouc–métal 32 presses compression, 4 presses d’injection

Machines pour sablage et encollage automatique

Découpe produits plats sur machine C.N.C caoutchouc polyuréthanne

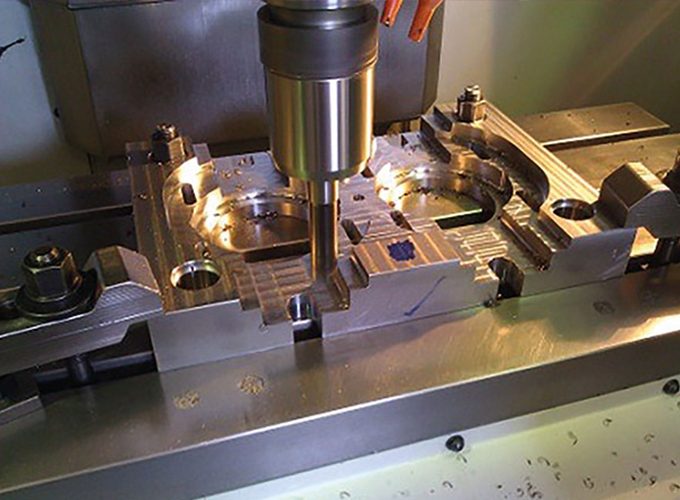

Fabrication des moules

Usinage polyuréthane

Atelier finition ébavurage1

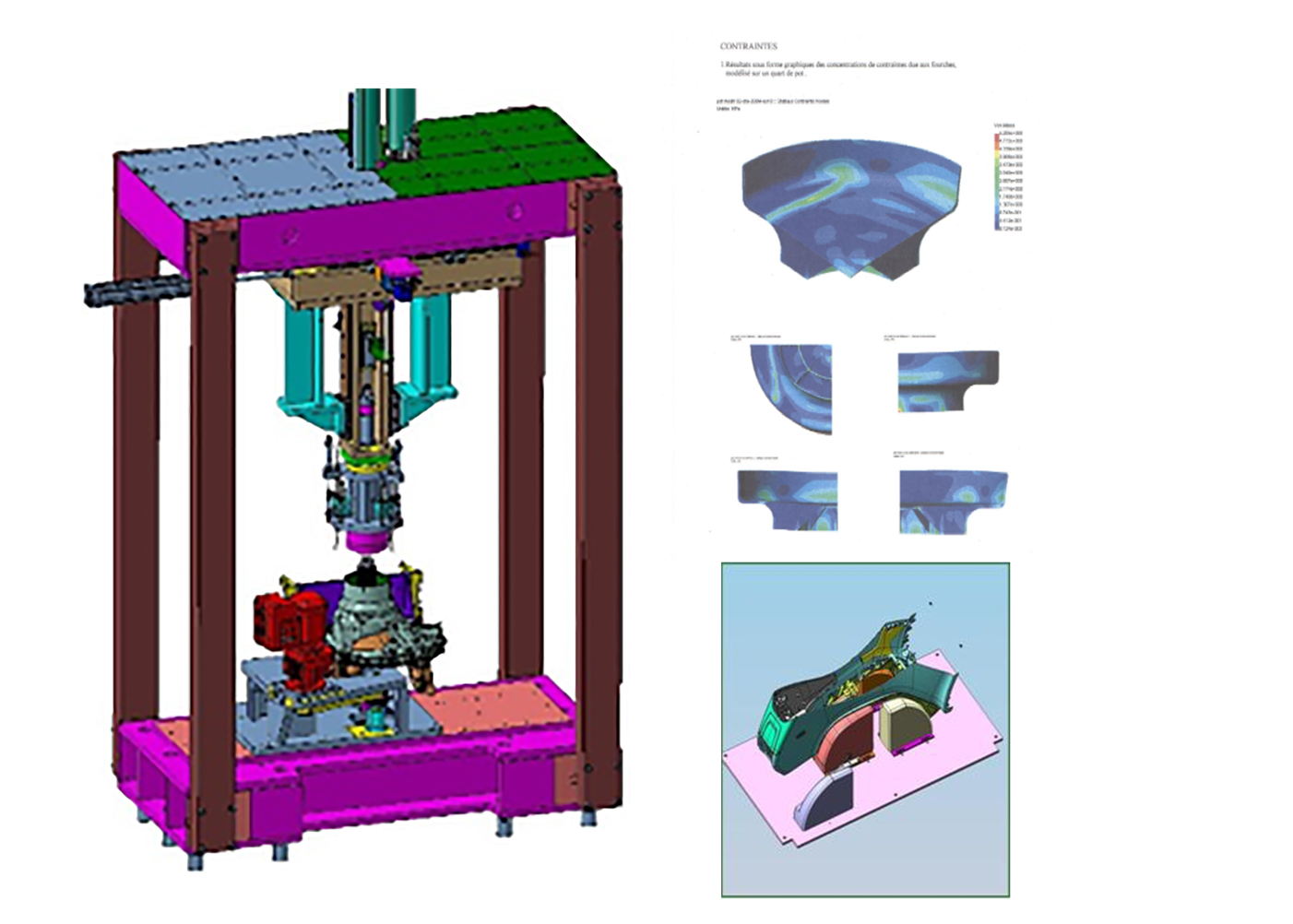

ÉTUDE PROJET

- Réalisation du cachier des charges en étroite collaboration avec nos clients.

- Design de la pièce.

- Calculation sur outil dédié des propriétés mécaniques de la pièce développé.

CONCEPTION

- Étude des outillages.

- Détermination des méthodes de fabrication.

- Suivi validation et qualité.

TESTS

- Validation prototype.

- Moyen d’essais : machines d’essais compression / traction 100 kN, banc de fatigue, essais abrasion, test D.R.C.